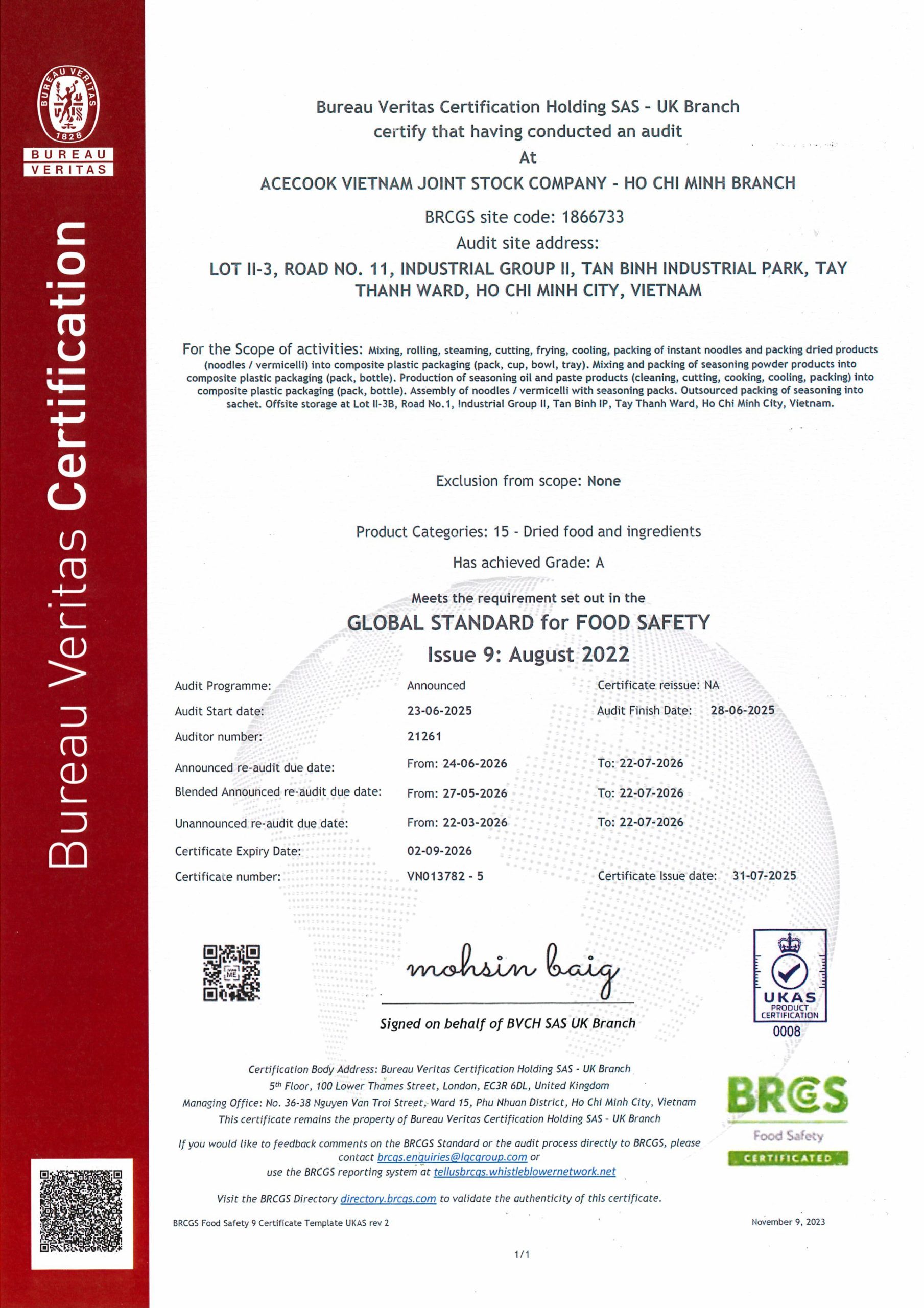

Each product undergoes a three-stage inspection process involving a metal detector, a checkweigher, and an X-ray foreign object detector. Non-conforming products are removed from the line and processed according to a separate, defined procedure.

Quality Assurance

QUALITY CONTROL & FOOD SAFETY

Raw Material Control

![]()

![]()

Production Process Control

![]()

![]()

Finished Product Control

![]()

![]()

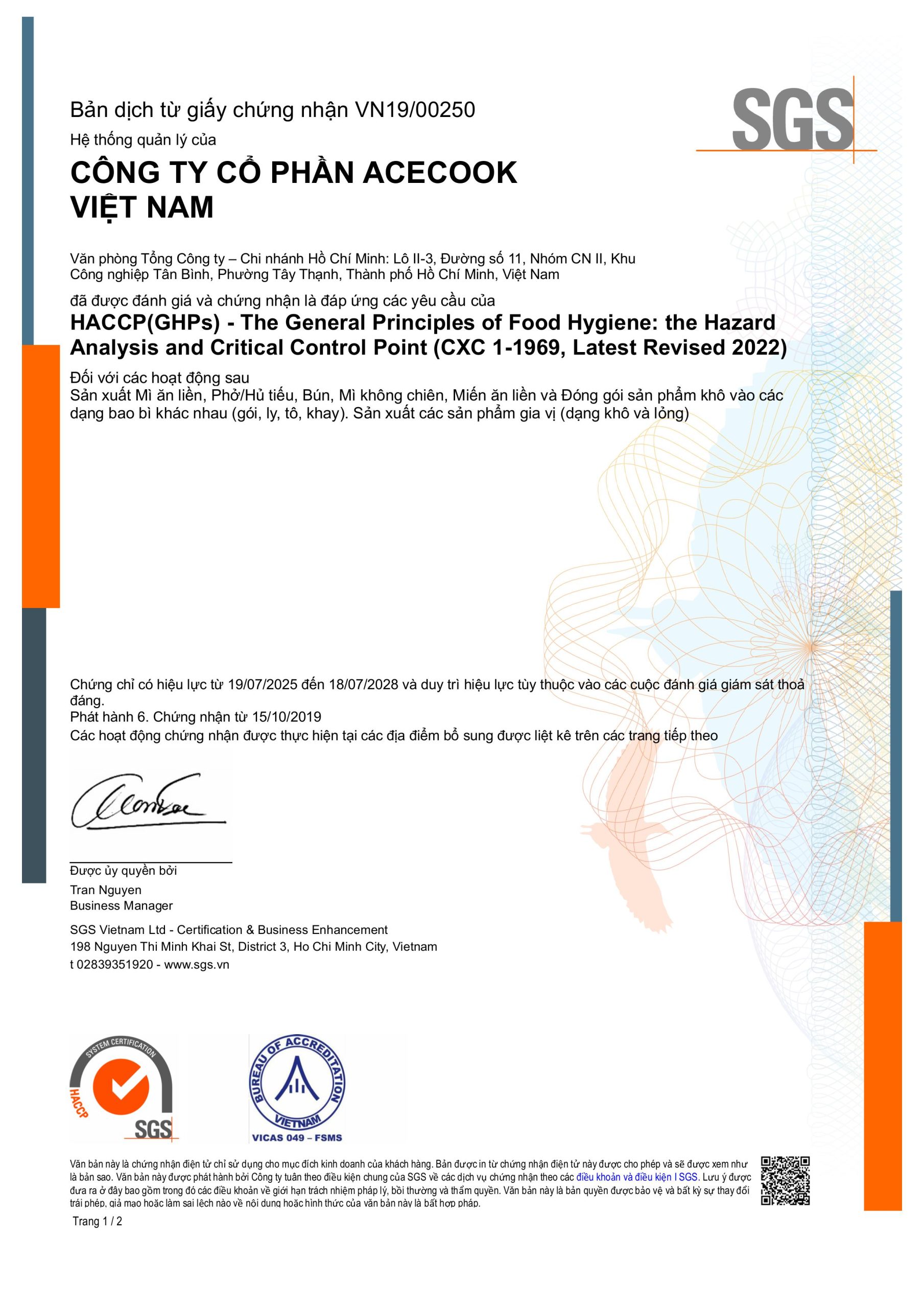

Raw Material Control

Acecook Vietnam’s raw materials are selected from reputable suppliers and rigorously evaluated based on three main criteria:

- Safety Standards: All raw materials must fully meet the requirements stipulated by both Vietnamese and international food safety and hygiene laws.

- Supplier Evaluation and Commitment: Suppliers are assessed before the commencement of transactions and are re-evaluated regularly every year. Suppliers must obtain certification for food safety, guarantee not to use non-approved additives, ensure that their products are non-genetically modified (NON-GMO), and comply with environmental standards.

- Quality Control: Raw materials undergo rigorous quality inspections and controls prior to production input. This includes a visual inspection of the supplier’s warehouse and transportation vehicles.

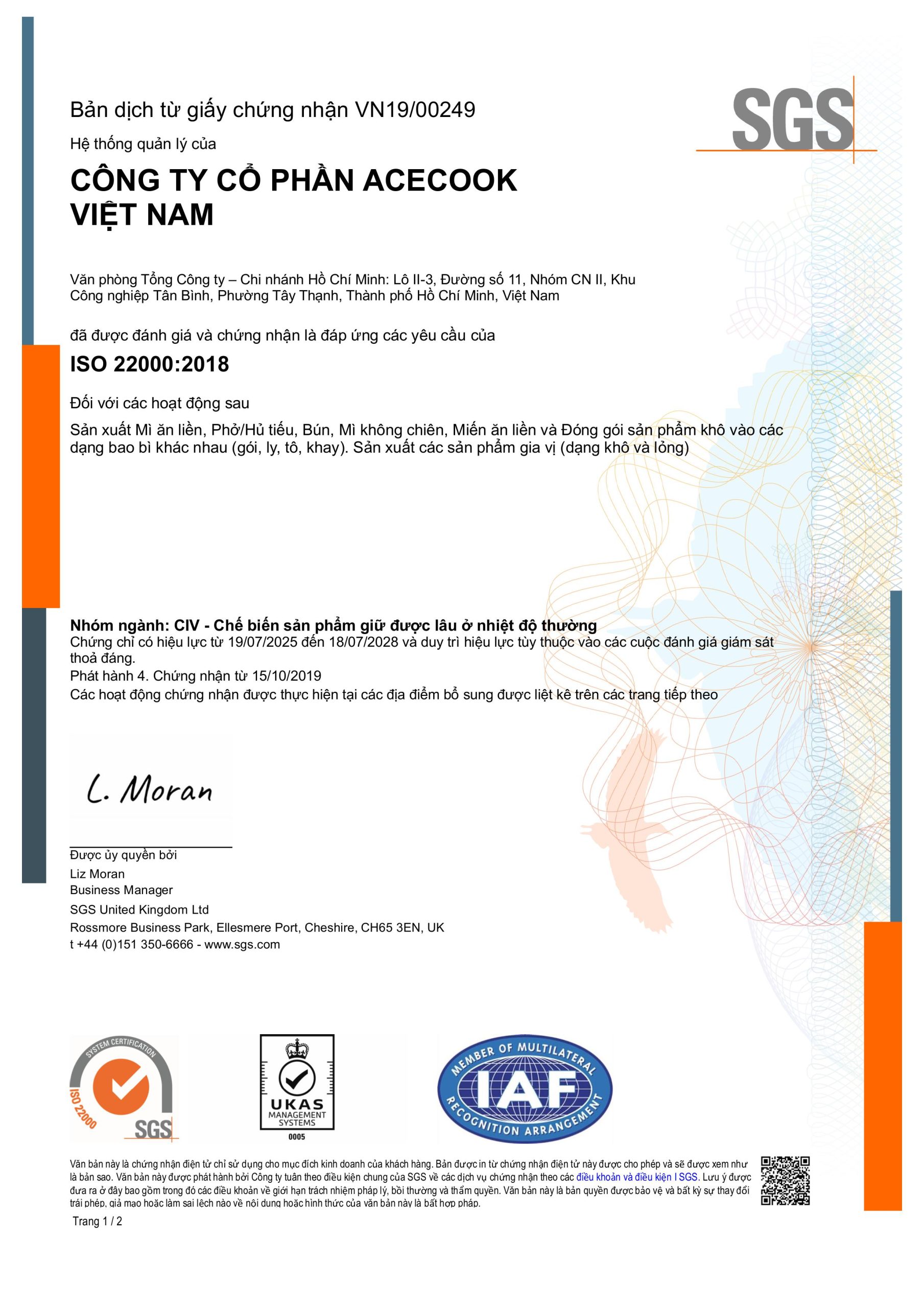

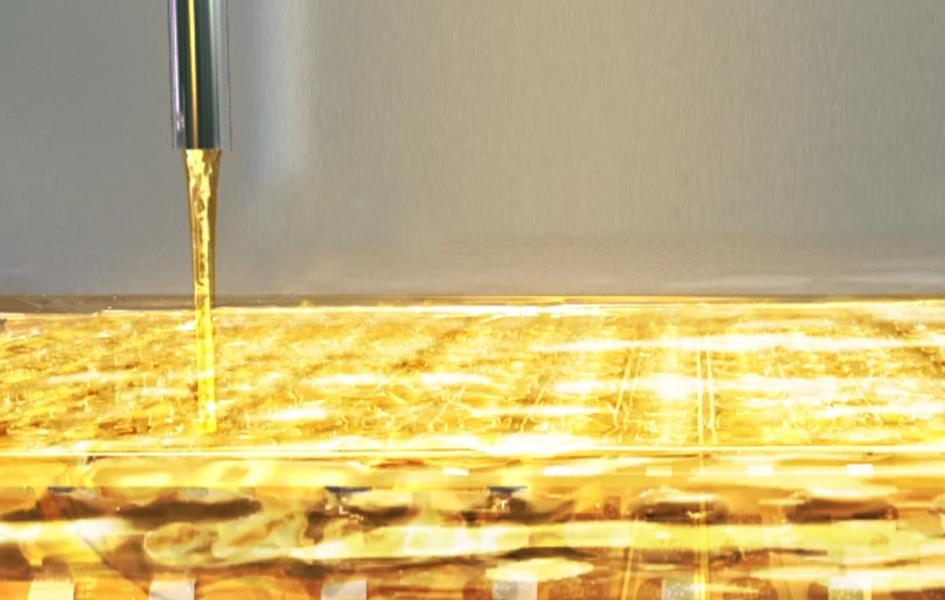

Production Process Control

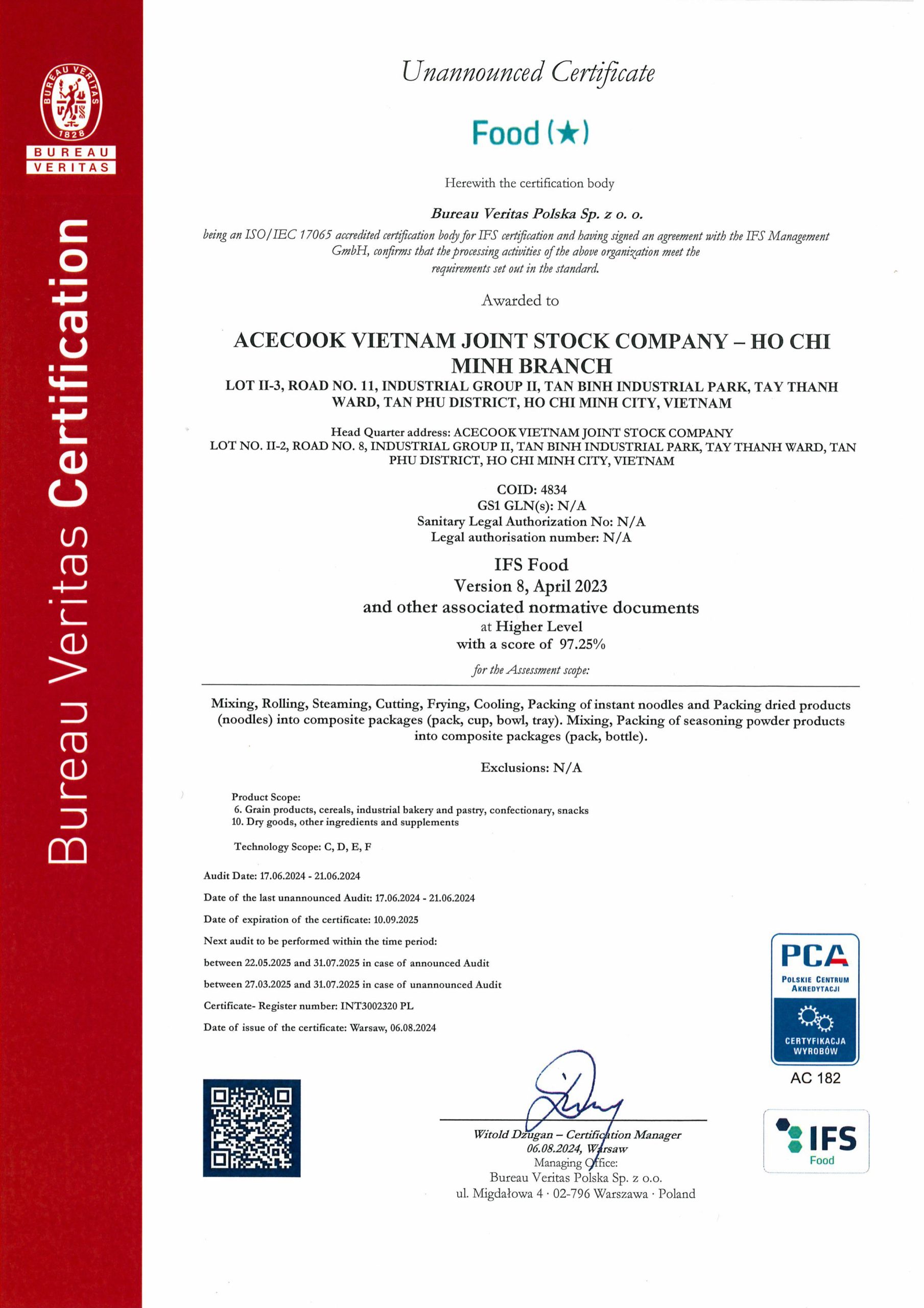

- IFS Food – Standard for Auditing Quality and Food Safety of Food Products

- BRCGS – Global Standard for Food Safety

- ISO 22000:2018 – International Standard for Food Safety Management Systems

- HACCP – Hazard Analysis and Critical Control Points System

Finished Product Control

Compliant with Vietnamese laws and export market regulations.

- Vietnamese Standard TCVN 7879:2008

- Legal regulations in Vietnam and export countries

LABORATORY

AUTHENTICATION SYSTEM

PRODUCT RESEARCH & DEVELOPMENT

PRODUCTION PROCESS

INVENTORY CONTROL &

PRODUCT DISTRIBUTION

Acecook Vietnam has modernized its inventory management system, enabling accurate real-time tracking and management of product quantities. This allows the company to optimize resources and improve operational efficiency.

In parallel, a broad and flexible distribution network ensures products reach consumers. Every stage, from factory to retailer, is rigorously monitored, contributing to the maintenance of quality and brand reliability both domestically and internationally.

Acecook’s inventory management and distribution system not only enhance competitiveness through improved operational efficiency but also strengthen its position as a leader in the instant noodle industry and build a solid foundation for future global expansion strategies.